Rover P5 and P5B Rear Leaf Spring Pads. One of the things I find fascinating about these cars is the history you can uncover, a history that stretches back to when Britain had a vibrant British-owned motor industry. The strangest things can trigger the search for this history, all made possible by the internet. I find this stuff fascinating.

A case in point is the rear leaf spring pads. These are small discs of plastic that fit at the end of the leafs in the rear springs. The idea being that as the spring flexes, the discs prevent the ends of the individual leafs from rubbing against each other, which causes thinning of the leaf and can lead to breakage. The pads also reduce friction (or ‘stiction’ in modern suspension terminology) and reduce noise as the leafs slide against each other.

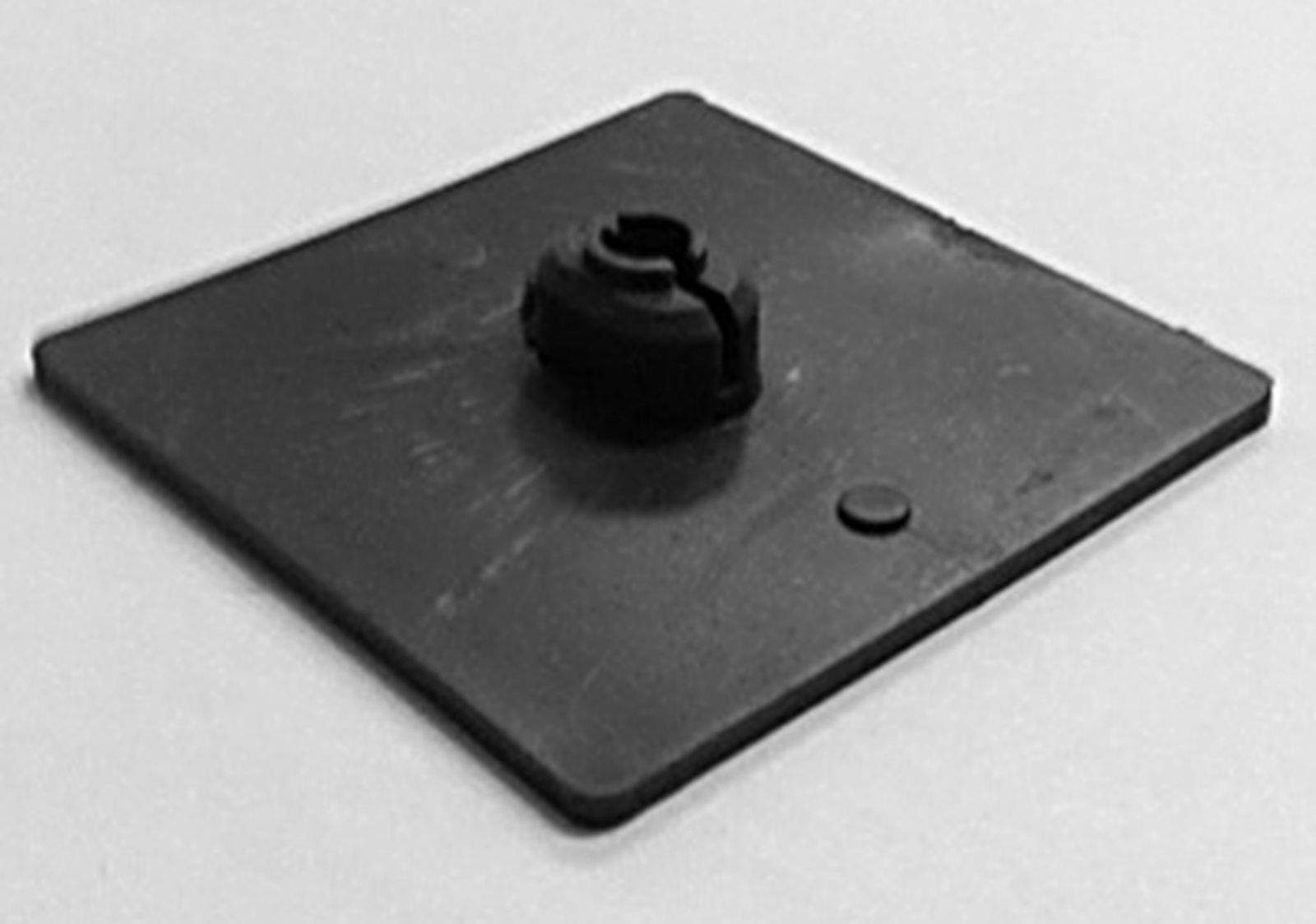

As part of refurbishing the rear leaf springs on my car, I decided to strip them down, and get them re-tempered and re-set, and I could then inspect them for wear and grease the leafs. Four of the leafs on the P5 and P5B have pads at the ends – basically thin plastic discs with a ‘pip’ on one side that fits in a hole in the leaf and prevents the pad moving around. These pads wear, but are no longer available, so owners either leave them out completely or make their own – I’ve seen Tupperware lids cut up, Pringles lids, and sheets of very soft Polyurethane used as replacements.

It seems to me that these pads take quite a beating, with the weight of the car sitting on them and then being slid around in a wet and gritty environment under the car. It’s surprising they last as well as they do, so what are they made of? Most people assume Polythene or Nylon of some sort, yet modern versions of the pads for other cars seem to be mainly from Polyurethane. The discs on my car are hard, not soft – more like Nylon than Polythene or soft Polyurethane. Or so I thought.

Some digging on the web reveals that in terms of abrasion resistance, Thermoplastic Polyurethane is by far the most resilient plastic (see here for details), so that seems like the ideal thing for these discs.

Here’s a close-up photo of one of the original discs from my car:

The reason the photo is so close is because I noticed that on one of the pads there was a patent number. After some digging trying to find patent details I found the European patent website Espacenet (it seems the British Patent Office don’t hold this information). I searched for the Patent Number (GB 722510) and to my amazement found it (see here) for “Improvements Relating To Laminated Springs”. Here is the original patent document: GB722510A.

So, not only do I now know that the idea was patented on 9 June 1952, but the patent is attributed to Alan Hodgson of J. BROCKHOUSE & COMPANY, LIMITED.

Further research uncovers that J Brockhouse had a factory in Wolverhampton and their Head Office was (and still is) in West Bromwich in the West Midlands. They started making springs and axles, but by the 1950’s had quite a diverse product range including machine tools (read more here). They’re still in business in 2015, still based in West Bromwich, specialising in forgings, CAD/CAM and machining (www.brockhouse.co.uk).

Back to the pads. The patent states that the pads are made from “a solid polymer of ethylene of high molecular weight…the material being known as Polythene…”. So there you have it. They were made from Polythene, not Nylon or other material.

Looking around to see if there are similar pads for other cars that might fit, it seems that all modern pads are made from Polyurethane. I’m no mechanical engineer, and I don’t know the relative merits of Polythene vs. Polyurethane (if anyone can help, please get in touch). However, whilst Thermoplastic Polyurethane seems to have the highest abrasion resistance, according to Wikipedia Polyurethane was only discovered in 1937, so perhaps it wasn’t widely available or economic to produce in the early 1950’s, when the patent was submitted.

So what to do – make my own from Polythene? Ebay to the rescue, and I found these pads which, whilst square, do have a retaining ‘pip’ and are the right size and thickness.

I ordered 16, and after a little cutting down of the ‘pip’ with a craft knife, they fit well. The ‘pip’ is too tall, and also slightly too wide (it’s actually oval rather than round), but after modifying they fit very well. They’re 2½ inches wide, and the springs are about 3 inches wide. They’re made from Polyurethane, but feel a similar hardness to the original pads (they aren’t at all soft). Time will tell how they last, although as I’m heavily greasing the springs and will wrap them in Denso tape and add vinyl gaiters, if they last another 47 years I may never see them again, unless I’m still here at 94.

Anyway, I find it fascinating that we can uncover so much information abut such a seemingly minor part of a car launched 57 years ago. Thank you Alan Hodgson and J. Brockhouse & Company, Limited.